Dec . 04, 2024 17:03 Back to list

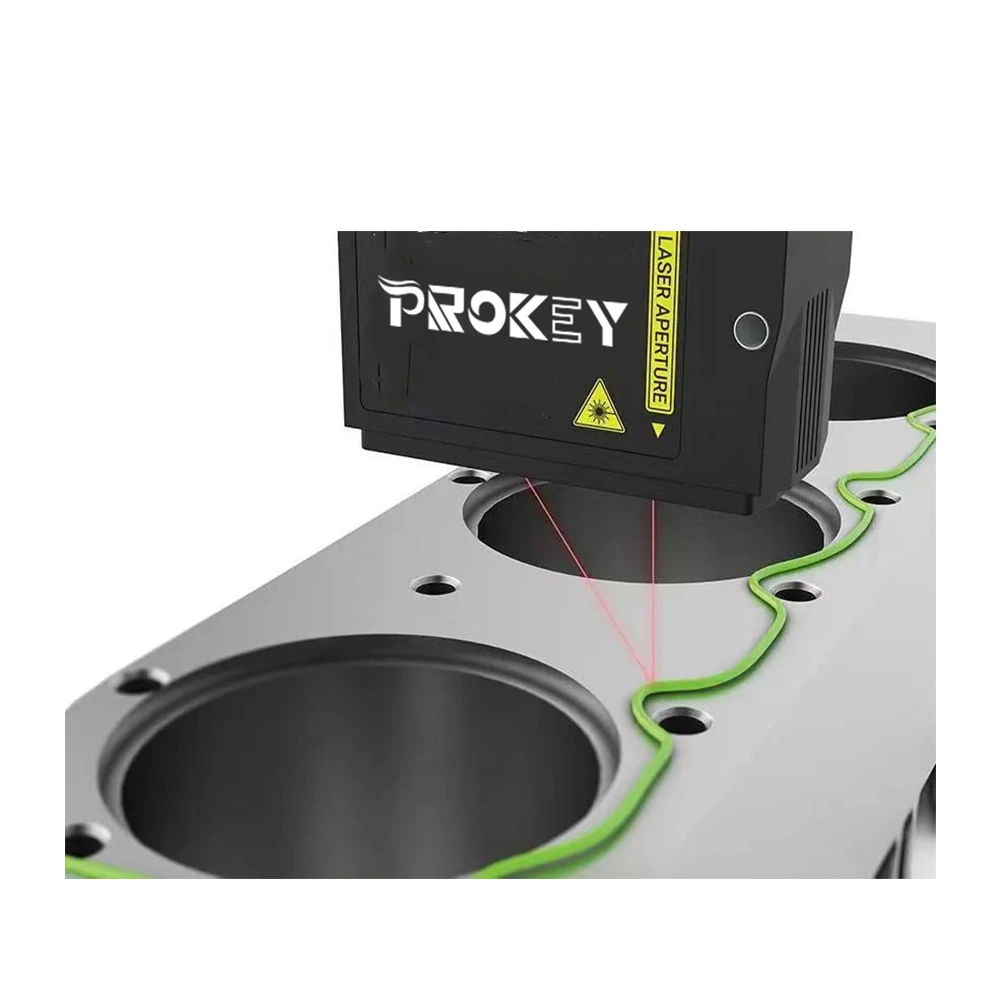

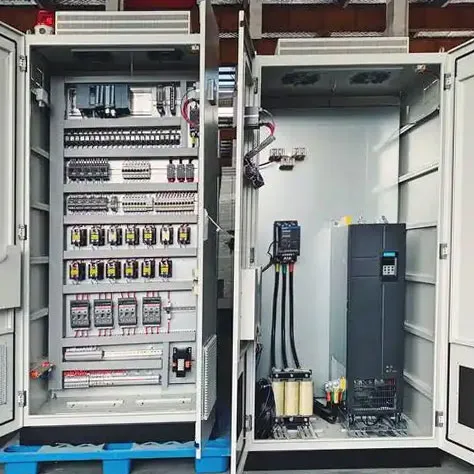

programmable machine controller

The Rise of Programmable Machine Controllers in Modern Manufacturing

In today’s fast-paced and ever-evolving manufacturing landscape, the integration of advanced technology has become imperative for maintaining competitiveness and efficiency. One of the most significant advancements in this domain is the advent of Programmable Machine Controllers (PMCs). These devices have transformed the way machines operate, manage processes, and enhance productivity across various industries.

A Programmable Machine Controller is an intelligent device that allows for the automatic control of machinery and processes within a factory setting. Unlike traditional controllers, which are often hard-wired and limited in function, PMCs are flexible, programmable, and capable of managing multiple tasks simultaneously. This flexibility enables manufacturers to quickly adapt to changing production needs, optimize workflows, and implement complex automation strategies.

The Rise of Programmable Machine Controllers in Modern Manufacturing

One of the key applications of PMCs is in robotics. With the integration of PMCs, industrial robots can perform intricate tasks such as assembly, welding, painting, and material handling with precision and consistency. This not only enhances product quality but also reduces labor costs and increases production rates. Furthermore, the use of PMCs in robotics allows for advanced features such as real-time monitoring, diagnostics, and adaptive control, which contribute to overall operational efficiency.

programmable machine controller

Moreover, the rise of Industry 4.0—a term that defines the current trend of automation and data exchange in manufacturing technologies—further amplifies the significance of PMCs. These controllers facilitate the seamless integration of machines with the Internet of Things (IoT), enabling real-time data exchange and facilitating smarter manufacturing processes. With data analytics, manufacturers can glean insights into machine performance, predict maintenance needs, and implement preventive measures, thereby reducing the risk of unexpected downtimes.

The scalability of PMCs is another noteworthy aspect. As businesses grow and evolve, their manufacturing processes often need to change accordingly. Programmable Machine Controllers can be easily scaled to accommodate larger operations or new manufacturing lines. This adaptability is crucial for organizations looking to expand their capabilities without incurring excessive costs or experiencing operational disruptions.

However, the implementation of PMCs is not without its challenges. While they offer numerous benefits, transitioning from traditional control systems to PMCs requires significant investment in both time and resources. Training personnel to effectively program and operate these systems is critical, as their complexity can be daunting for those accustomed to conventional methods. Additionally, ensuring cybersecurity in an increasingly connected environment is paramount, as PMCs can become potential targets for cyber threats.

In conclusion, the introduction of Programmable Machine Controllers has revolutionized the manufacturing industry by providing unparalleled flexibility, efficiency, and adaptability. As companies continue to navigate the demands of a rapidly changing market, the ability to reprogram and optimize machinery will be essential for sustained success. With the ongoing advancements in technology and the rising tide of Industry 4.0, PMCs will undoubtedly play a crucial role in shaping the future of intelligent manufacturing. Embracing this technology is not merely a choice but a necessity for those aiming to thrive in the competitive landscape of modern industry.

-

Why Steel Mills Rely on FODA’s High-Temperature Cylindrical Roller Bearings?

NewsApr.10,2025

-

What is a Plain Bearing? A Complete Guide to Design & Functionality

NewsApr.10,2025

-

Thrust Ball Bearings vs. Tapered Roller Bearings: FODA’s Performance Comparison

NewsApr.10,2025

-

The Engineering Behind FODA Thrust Ball Bearings: Precision for High-Speed Applications

NewsApr.10,2025

-

No More Compromises: Get Precision-Engineered Custom Bearings Tailored to Your Exact Specifications

NewsApr.10,2025

-

In-Depth Analysis: Application Differences of Different Types of Angular Contact Ball Bearings

NewsApr.10,2025

Products categories